Sputter/Evaporation Dual Chamber System (AJA Orion)

Commissioned in Feb. 2013

|

|

|

The system is designed for 3-inch

wafers, with substrate rotation 0-40 rpm and heating up to 850°C. System base

pressure is better than 1×10-8 torr. The magnetron sputter chamber

is equipped with 10 sputter guns, and RHEED growth monitoring. The

evaporation chamber is equipped with one e-gun (5-pocket, 5kW) and four

thermal sources, plus an atomic gas source for the reactive growth of oxides

and nitrides. An additional wafer handler enables substrate tilting during

evaporation. The load-lock chamber is equipped with a 6-cassette shadow mask

changing system. |

Diamond CVD (SEKI AX5250M)

Commissioned in June 2012

|

|

The AX5250 microwave plasma

reactor incorporates 5 kW at 2.45 GHz microwave generator to produce plasmas

at high power densities. Such operation allows a new regime of plasma

chemistries. This reactor at our facility is dedicated to synthesizing high

quality single crystal and poly crystalline diamond. Light doping, e.g., with

Nitrogen, is facilitated with the natural presence of impurities in the

processing gases, while heavy doping, e.g. with Boron/Phosphorus, is achieved

by introducing additional gas channels. The system can accommodate up to

three dopant gases. The maximum wafer size 2”, and the maximum processing

temperature 1100°C. |

XRD (Bruker D8 Discover)

Commissioned in May 2013

|

|

This X-ray analyzer is capable of

performing high-resolution X-ray diffraction, gracing incidence diffraction,

reflectometry, and reciprocal space mapping. It consists of a centric Euclerian cradle with Chi/Phi rotations and X-Y-Z

translations; high resolution optics with a Ge 2-bounce monochromator, a

3-bounce pathfinder, and fully automated slits; a Göbel mirror for Cu

radiation. The system is equipped with a vacuum chuck holding up to 5”

wafers. |

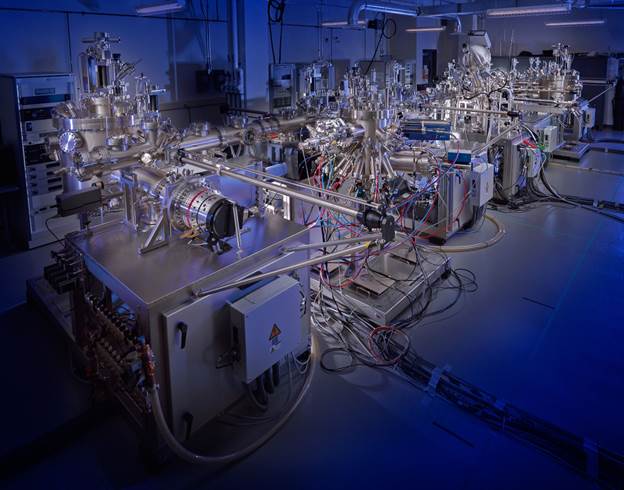

UHV Cluster Deposition System

(Omicron)

(commissioned in Dec. 2014)

|

|

|

This large scale thin film

deposition system has three Molecular Beam Epitaxy (MBE) systems, two

magnetron sputter systems, and one surface analysis module, all

interconnected through a linear transfer line. This system is uniquely

designed to combine the three major spin systems, magnetism,

superconductivity, and quantum spin Hall state, completely in situ under ultra-high vacuum and

maintain the cleanest interfaces possible. The three MBEs are dedicated to

perovskite oxides (YBaCuO, SrTiO,

LaSrMnO, etc.), metal / ferrites (XFe2O4)

/ binary compounds (MgB2 etc.), and topological insulators (Bi/Te/Se with Cu/Ca/Cr doping), respectively. The metal MBE

chamber is equipped with an additional 6-cell linear e-gun. The two sputter

systems are devoted to depositing more conventional magnetic materials (12

guns) and superconductors (8 guns), respectively. The analysis module enables

sensitive surface characterizations with XPS (X-ray photoelectron

spectroscopy) / AES (Auger electron spectroscopy) / UPS (ultra-violet photoelectron

spectroscopy), and is equipped with an ion sputter gun for depth

profiling. A sample preparation

sub-chamber, located right next to the load-lock, allows for well controlled

device surface treatment before, after, or in between film growths

(annealing, ion milling, oxidation / nitridation, etc.). Shadow mask assembly

is available in the load-lock, substrate tilting in the metal MBE, atomic gas

sources in both oxide and metal MBEs, and RHEED in all three MBEs. The system

base pressure is 1×10-10 torr for MBE / surface analysis, and 1×10-9

torr for sputtering. The standard wafer size is 2”. Maximum substrate

temperature is 1100°C in the MBE systems, 850°C in the sputter systems, and

527°C in the analysis module. The system has detachable vacuum transfer

shuttles for transporting delicate specimen, while maintaining under UHV,

into other growth/characterization systems, for example, to the ALD (atomic

layer deposition) / PECVD (plasma enhanced chemical vapor deposition)

deposition systems (located at QNC on campus) for the growth of high quality

dielectrics and semiconductors, or to the Canadian Light Source beam lines

for advanced ARPES analysis (Angle-resolved photoemission spectroscopy). |